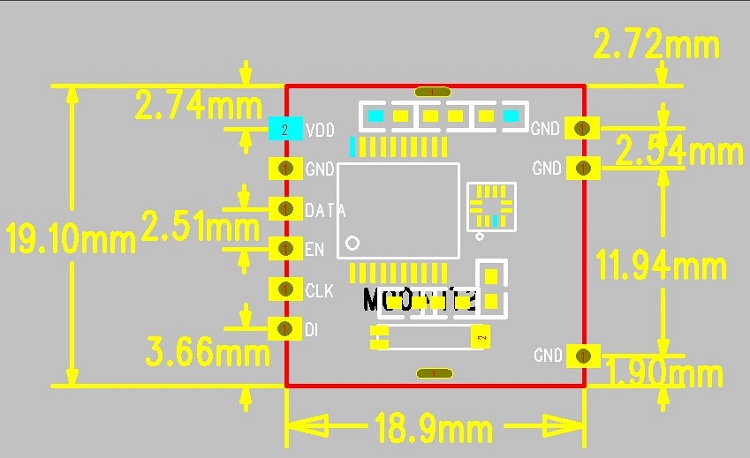

STP201M : IIC Interface Wrist Applicaton 3D Pedometer Module

Package : IC

Interface: IIC

Application: Wrist

Size:9*8.72

| Parameter | Condition | Performance | Unit | ||

| Min | Typ | Max | |||

| Working voltage | 2.3 | 3 | 3.6 | V | |

| Working current | @3V | l | 20 | uA | |

| Pedometer resolution | 1 | Step | |||

| Working temperature | -40 | 85 | ℃ | ||

| Special Function | Pedometer module |

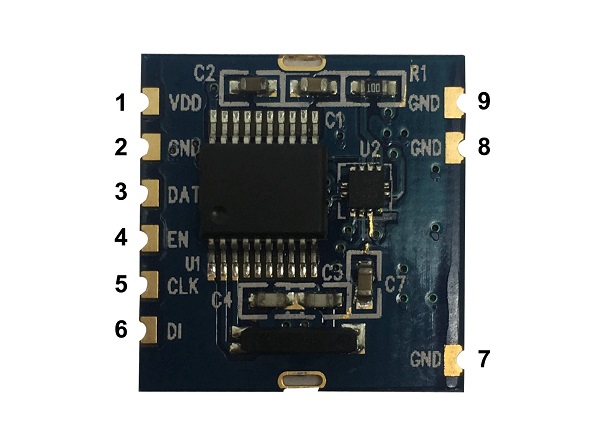

| Pin number | Pin name | Description |

| 1 | VDD | Connected power supply |

| 2,7,8,9 | GND | Power ground |

| 3. | DATA | Data output |

| 4 | EN | Communication enable input, high effective, usually low. After EN is high, it needs to delay 100ms to start communication |

| 5 | CLK | Communication clock signal input, CLK is high and DATA changes, CLK is low, the master reads DATA |

| 6 | D1 | NC |

Privacy Policy

· Privacy Policy

There is currently no content available

Email:sales@nicerf.com

Tel:+86-755-23080616