How to properly clean the residue after soldering on the wireless module PCB board

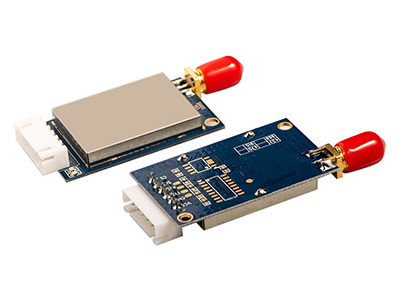

With the rapid development of the Internet of Things, a large number of wireless module communication products have emerged in the field of wireless communication. Regardless of the small size of the module, there are many processes in the production process before it can finally be delivered to the customer. Regarding the problem of residues on the wireless module PCB board after soldering, this article will introduce in detail the method of cleaning the wireless module.

After the wireless data transmission module PCB board is welded to the antenna SMA head, some flux, rosin and other substances will remain on the surface. At this time, you can use board washing water (commonly known as circuit board cleaner) to clean the wireless module after cleaning. To be clean, the cleaning steps are as follows:

- Prepare special cotton swabs, washing water, rubber gloves, and masks. Because washing water is a chemical substance that is easy to evaporate, inhalation is irritating to the respiratory tract and lungs; in addition, washing water is corrosive to the skin, so Put on a mask, silicone gloves and other protective measures before cleaning.

- Squeeze the special cotton swab into the mouth of the bottle containing the plate washer water. The bottle mouth will have the plate washer water squeezed out. Note: an appropriate amount is fine.

- Take up the cotton swab and gently wipe the place where there is rosin residue near the welding SMA head. If it is not wiped clean, repeat the above procedure until it is wiped clean.

- Put the clean wireless module into the designated box.

If there is dust and debris on the shielding cover of the wireless module, you can fold the special paper towel into about 3 layers, and use the folded paper towel to squeeze the mouth of the small bottle containing the plate washer water, and squeeze out an appropriate amount of plate washer water. Wipe the top of the shielding cover from left to right at a time. If it is not clean, you can wipe it again.

The above is the correct way to clean the welding residue of the wireless module PCB board. If it is to clean the dust and debris on the shielding cover, you can also wipe it with a paper towel dipped in board washing water. It is worth noting that the washing water has a peculiar smell and is corrosive to the skin in contact with it. When using the washing water to clean the module, you should take protective measures to protect yourself from the damage of the washing water.

+86-755-23080616

+86-755-23080616

sales@nicerf.com

sales@nicerf.com

Website: https://www.nicerf.com/

Address: 309-314, 3/F, Bldg A, Hongdu business building, Zone 43, Baoan Dist, Shenzhen, China